Impulse testing of cables is a crucial process that assesses the ability of cables to withstand sudden voltage surges. These surges, also known as impulses, can occur due to lightning strikes, switching operations, or other transient events. By subjecting cables to controlled impulse voltages, engineers can evaluate their insulation integrity and overall reliability.

Types of Impulse Tests

There are several types of impulse tests conducted on cables, including standard lightning impulse tests, chopped lightning impulse tests, and switching impulse tests. Each test simulates different real-world scenarios to ensure that cables can withstand a variety of voltage surges and transient disturbances.

Importance of Impulse Testing

Impulse testing of cables is essential to ensure the safety and reliability of electrical systems. Cables that fail to withstand impulse voltages can lead to short circuits, equipment damage, and even fires. By identifying potential weaknesses through impulse testing, engineers can prevent catastrophic failures and protect both people and property.

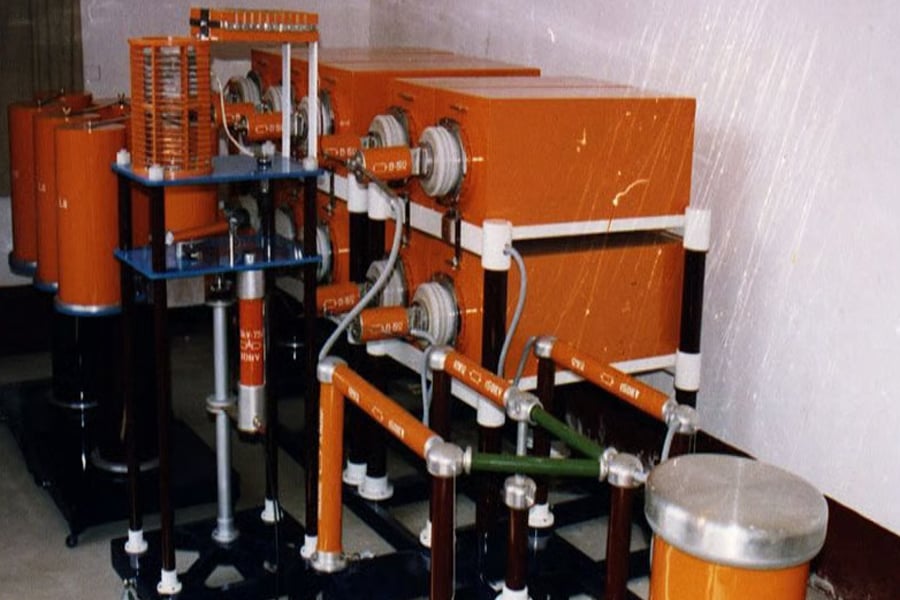

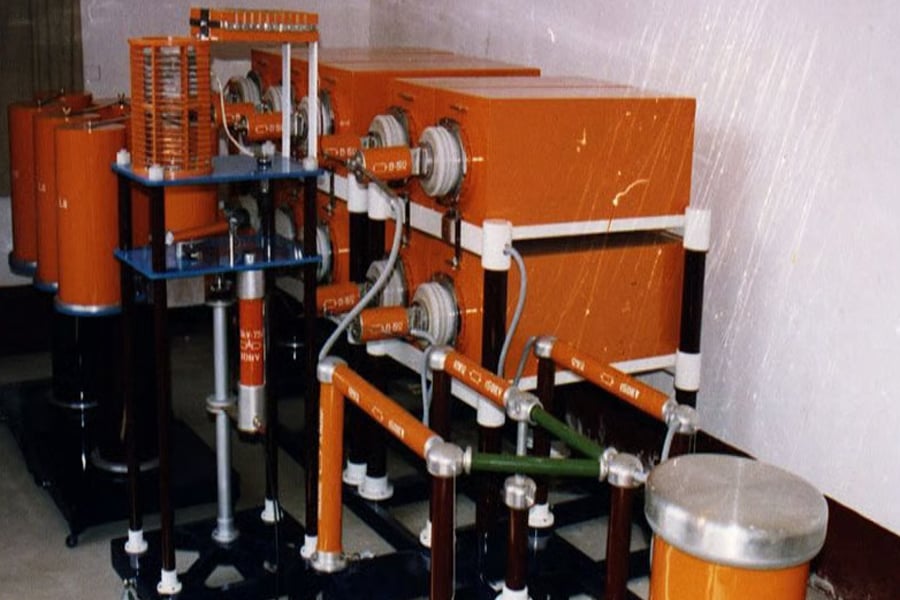

Testing Procedures

During impulse testing, cables are subjected to high-voltage impulses with specific waveforms and durations. The test results are carefully analyzed to assess the insulation condition, discharge behavior, and overall performance of the cables. Any anomalies or deviations from expected results can indicate potential issues that need to be addressed.

Industry Standards

Impulse testing of cables is governed by industry standards and regulations to ensure consistency and accuracy across different testing facilities. Standards such as IEC 60230 and IEEE 1313 provide guidelines for conducting impulse tests and interpreting the results. Adhering to these standards is crucial for guaranteeing the effectiveness of the testing process.

Benefits of Impulse Testing

The benefits of impulse testing of cables are manifold. By proactively testing cables for impulse withstand capability, industries can minimize the risk of costly downtime, equipment failure, and safety hazards. Regular impulse testing also helps in identifying potential insulation weaknesses before they escalate into serious issues.

Challenges in Impulse Testing

Despite its importance, impulse testing of cables presents certain challenges. Testing large cables or long cable lengths can be logistically complex, requiring specialized equipment and testing setups. Additionally, interpreting the test results accurately and implementing corrective measures based on the findings can be demanding tasks.

Quality Assurance

Impulse testing plays a critical role in quality assurance for cable manufacturers and installers. By subjecting cables to rigorous impulse tests before deployment, manufacturers can verify the quality of their products and ensure compliance with industry standards. This proactive approach helps in building trust with customers and enhancing the overall reputation of the brand.

Future Trends in Impulse Testing

As technology advances and electrical systems become more sophisticated, the demand for reliable impulse testing methods is expected to rise. Innovations in testing equipment, data analysis techniques, and simulation software will drive improvements in the accuracy and efficiency of impulse testing. Keeping pace with these developments will be crucial for ensuring the safety and reliability of cable systems.

Conclusion

In conclusion, impulse testing of cables is a vital process that safeguards the integrity and performance of electrical systems. By subjecting cables to controlled impulse voltages and analyzing the test results, engineers can identify potential weaknesses and mitigate risks before they escalate. Adhering to industry standards, investing in quality testing procedures, and staying abreast of technological advancements are essential for ensuring the safety and reliability of cable systems in the modern era.

Quote Inquiry

contact us