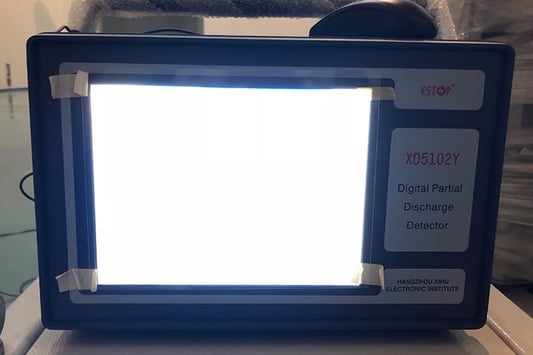

What is HV test instrumentation?HV test instrumentation is a critical component in the electrical industry that is used to measure and test high voltage equipment to ensure they are operating safely and efficiently. This equipment is essential for maintaining the integrity of power systems and preventing costly downtime.Types of HV test instrumentationThere are various types of HV test instrumentation available in the market, including insulation testers, partial discharge testers, transformer testers, and circuit breaker analyzers. Each type serves a specific purpose in evaluating the condition of high voltage equipment.Importance of HV testingHV testing is crucial in identifying potential faults or weaknesses in electrical systems before they escalate into major issues. Regular testing can help prevent accidents, reduce downtime, and extend the lifespan of high voltage equipment.Benefits of using HV test instrumentationBy using HV test instrumentation, companies can improve the reliability and safety of their electrical systems, comply with industry regulations, and minimize the risk of equipment failure. This proactive approach can save businesses time and money in the long run.Key features to look forWhen selecting HV test instrumentation, it's important to consider factors such as accuracy, reliability, ease of use, and durability. Look for instruments that offer advanced technology, data logging capabilities, and remote monitoring options for added convenience.Industry applicationsHV test instrumentation is used across various industries, including power generation, transmission and distribution, manufacturing, and renewable energy. It plays a vital role in ensuring the smooth operation of electrical systems and preventing costly disruptions.Challenges in HV testingDespite the benefits of HV test instrumentation, there are challenges associated with testing high voltage equipment, such as safety risks, complex testing procedures, and the need for skilled technicians. Overcoming these challenges requires proper training and adherence to safety protocols.Latest trends in HV test instrumentationAdvancements in technology have led to the development of innovative HV test instrumentation with features like wireless connectivity, cloud-based data storage, and real-time monitoring. These trends are revolutionizing the way electrical systems are tested and maintained.Future outlookAs the demand for reliable and efficient electrical systems continues to grow, the importance of HV test instrumentation will only increase. Companies that invest in high-quality testing equipment and training for their technicians will stay ahead of the curve in the evolving electrical industry.Quote Inquirycontact us