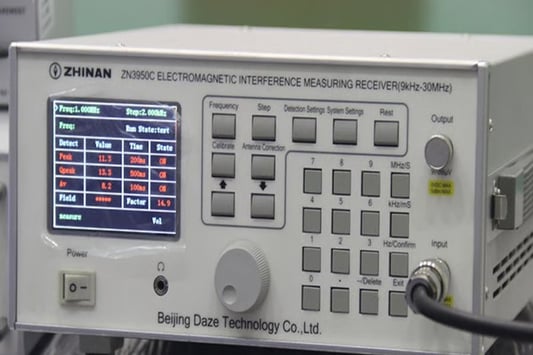

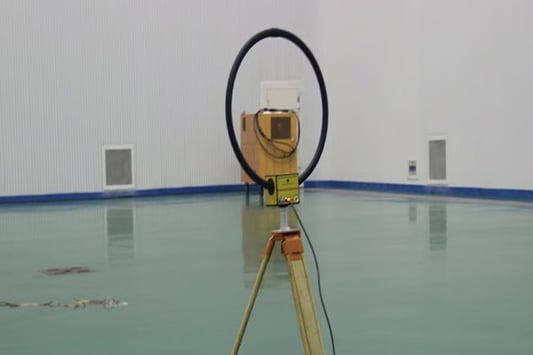

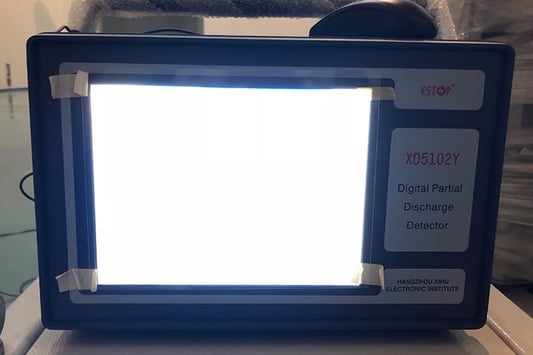

What is high voltage measurement?High voltage measurement is the process of determining the electrical potential difference across a circuit or component that is operating at high levels of voltage. This is a crucial aspect of electrical engineering and is used in a wide range of industries such as power distribution, automotive, and manufacturing.The Importance of Accurate MeasurementsAccurate high voltage measurements are essential for ensuring the safety and reliability of electrical systems. A small miscalculation in voltage levels can lead to catastrophic failures, equipment damage, and even pose a risk to human life. By utilizing precise measurement techniques, engineers can identify potential issues before they escalate.Common High Voltage Measurement TechniquesThere are several techniques used for high voltage measurement, including capacitive voltage dividers, resistive voltage dividers, and digital multimeters. Each method has its own advantages and limitations, depending on the specific requirements of the application.Challenges in High Voltage MeasurementOne of the main challenges in high voltage measurement is the risk of electrical breakdown or arcing, which can damage the measuring equipment and pose a safety hazard. Engineers must take precautions such as using appropriate insulation materials and maintaining a safe distance from high voltage sources.Types of High Voltage Measurement DevicesThere are various devices designed specifically for high voltage measurement, such as voltage probes, high voltage oscilloscopes, and power analyzers. These instruments are calibrated to withstand high voltage levels and provide accurate readings for troubleshooting and analysis.Calibration and Testing ProceduresCalibration is a critical step in ensuring the accuracy of high voltage measurement devices. Regular testing and calibration procedures help maintain the reliability of the equipment and minimize the risk of errors in voltage readings. It is essential to follow manufacturer guidelines and industry standards for calibration.Applications of High Voltage MeasurementHigh voltage measurement is used in a wide range of applications, including power generation, electric vehicles, renewable energy systems, and high-power electronics. Accurate voltage measurements are vital for optimizing performance, reducing energy consumption, and ensuring the safety of electrical systems.Future Trends in High Voltage MeasurementWith advancements in technology, high voltage measurement devices are becoming more compact, accurate, and versatile. Trends such as remote monitoring, wireless connectivity, and cloud-based data analysis are shaping the future of high voltage measurement, making it easier for engineers to gather real-time data and make informed decisions.Best Practices for High Voltage MeasurementTo ensure reliable and accurate high voltage measurements, engineers should always follow best practices such as proper grounding, using appropriate PPE (personal protective equipment), and conducting regular maintenance checks on measurement equipment. Safety should always be the top priority when working with high voltage systems.ConclusionHigh voltage measurement plays a crucial role in the operation and maintenance of electrical systems across various industries. By understanding the principles, techniques, and challenges involved in high voltage measurement, engineers can effectively troubleshoot issues, optimize performance, and ensure the safety of electrical systems.Quote Inquirycontact us